The SLEC series evaporative condensers feature a single-sided air inlet design, ensuring efficient heat dissipation while optimizing space utilization. Under standard operating conditions, they provide heat dissipation from 155KW to 6926KW, making them ideal for high-demand cooling applications.

Key Features:

- Single-Sided Air Inlet Design: Allows for flexible installation in limited spaces.

- High Cooling Capacity: Supports 155KW to 6926KW heat dissipation.

- Durable Construction:

- Z-700 (G235) hot-dip galvanized steel sheet casing for corrosion resistance.

- Aviation-grade aluminum alloy ventilation fan for optimal airflow efficiency.

- Integral hot-dip galvanized elliptical steel coil for improved heat exchange.

- Energy Efficiency: Designed for low energy consumption with maximum cooling performance.

- Low Maintenance: Built for durability and long service life with minimal upkeep.

Applications:

The SLEC series evaporative condensers are ideal for:

- Large-scale commercial and industrial refrigeration systems.

- Cooling solutions for extensive data centers.

- Heavy-duty cooling applications requiring high thermal performance.

With its single-sided air inlet, wide heat dissipation range, and robust design, the SLEC series evaporative condensers provide an efficient, space-saving, and reliable cooling solution for large-scale refrigeration needs.

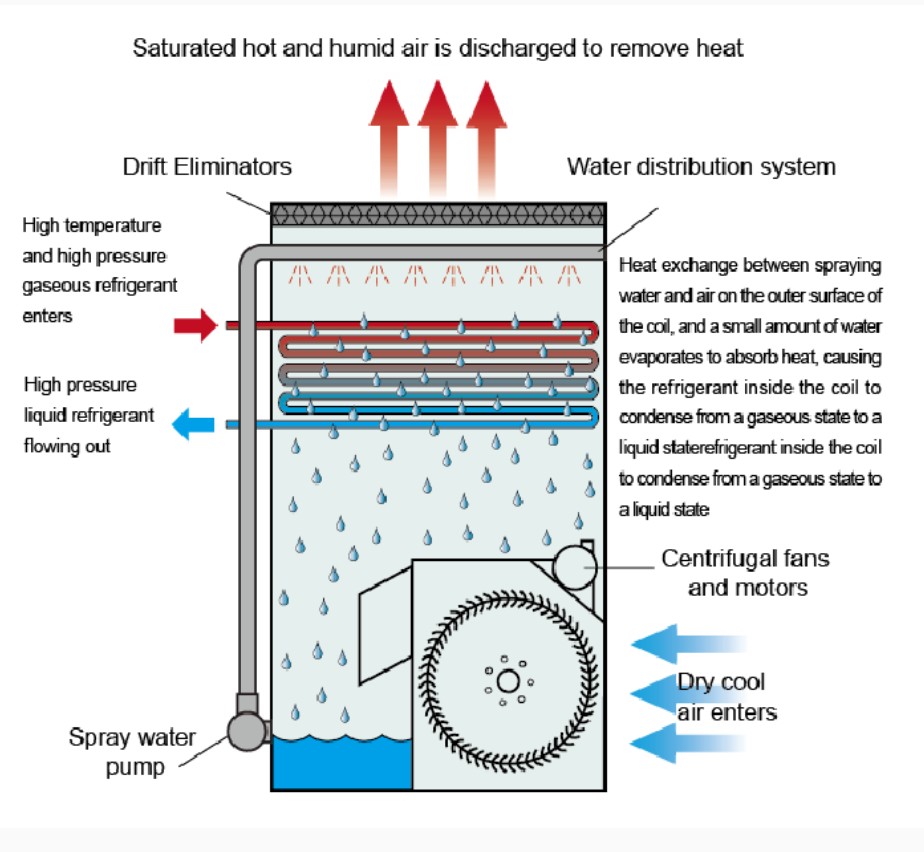

The high-temperature and high-pressure gaseous refrigerant working fluid from the refrigeration compressor enters the inside of the serpentine heat exchange coil from the side of the evaporative condenser, while the external water in the water pan of the evaporative condenser is evenly sprayed onto the surface of the serpentine heat exchange coil through the bottom water pump and upper spray system: The centrifugal fan located at the bottom of the cooling tower blows dry and cold air from the side into the interior of the cooling tower. The dry and cold air enters through the lower air intake grille and flows from bottom to top onto the surface of the serpentine heat exchange coil, where it undergoes counter current heat exchange with the external water on the surface of the serpentine heat exchange coil: A small amount of water evaporates into the air to take away heat. condensing the high-temperature and high-pressure gaseous refrigerant working fluid inside the coil. The humid and hot air is discharged from the top of the cooling tower. and the condensed liquid refrigerant flows to the storage tank or evaporator.