The SMCC-S closed cooling tower adopts an efficient counterflow modular design. and the entire series has obtained the CTI heat transfer performance certification from the United States. Under standard operating conditions. the water flow rate can range from 50 tons/hour to 1200 tons/hour. The standard configuration includes Z-700 (G235) hot-dip galvanized steel sheet casing. aviation grade aluminum alloy ventilation fan. and integral hot-dip galvanized elliptical steel coil.Suitable for central air conditioning in large commercial buildings, process water cooling in industrial plants. and large data centers. Suitable for central air conditioning in large commercial buildings. process water cooling in industrial plants. and large data centers.

The SMCC-S Series from Snowcoil represents a significant advancement in cooling technology, designed specifically for applications that demand high efficiency and sustainability. This series is characterized by its innovative evaporative cooling systems, which are engineered to optimize performance while minimizing environmental impact.

Key Features of the SMCC-S Series

- Advanced Cooling Technology: The SMCC-S Series utilizes cutting-edge evaporative cooling techniques that enhance energy efficiency. By leveraging the natural cooling properties of water, these systems significantly reduce energy consumption compared to traditional cooling methods.

- Sustainability Focus: Snowcoil prioritizes sustainability in its product design. The SMCC-S Series contributes to water conservation efforts by utilizing less water than conventional systems while maintaining optimal cooling performance. This aligns with global trends towards reducing environmental footprints in industrial operations.

- Customizable Solutions: Understanding that different industries have unique requirements, the SMCC-S Series offers customizable configurations. This flexibility allows businesses to tailor the cooling solutions to their specific operational needs, ensuring maximum efficiency and reliability.

- Durability and Reliability: Built with high-quality materials and advanced engineering practices, the SMCC-S Series is designed for longevity and dependable performance. This durability translates into lower maintenance costs and reduced downtime for users.

- Innovative Design: The design of the SMCC-S Series incorporates features that facilitate easy installation and operation. Its compact design allows for integration into various settings without requiring extensive modifications to existing infrastructure.

Applications

The SMCC-S Series is suitable for a wide range of applications across multiple industries, including:

- Industrial Cooling: Ideal for manufacturing facilities where process cooling is critical.

- Data Centers: Provides efficient cooling solutions to maintain optimal operating temperatures for sensitive equipment.

- Food Processing: Ensures temperature control in environments where food safety is paramount.

- HVAC Systems: Enhances the efficiency of heating, ventilation, and air conditioning systems in commercial buildings.

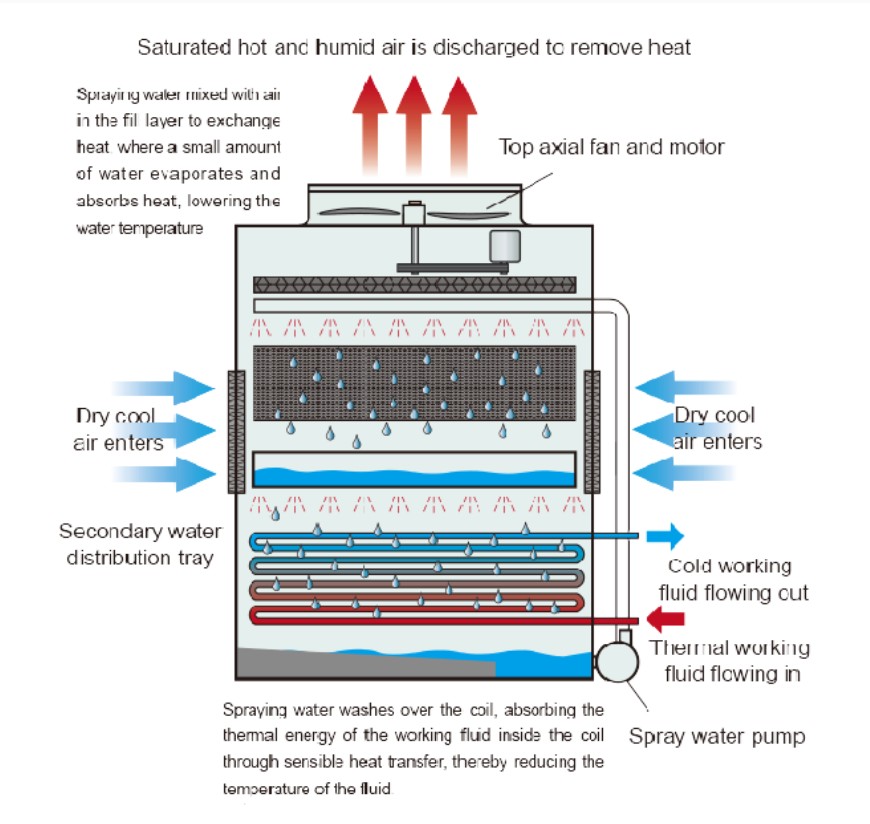

The high-temperature working fluid from the user side enters the inside of the serpentine heat exchange coil through the side of the closed cooling tower. while the external water in the water tray of the closed cooling tower is evenly sprayed onto the surface of the heat exchange packing through the bottom water pump and upper spray system; The axial flow fan located at the top of the cooling tower draws the surrounding dry and cold air into the interior of the cooling tower. The dry and cold air enters through the lower air intake grille and then flows from bottom to top into the heat exchange packing layer, where it undergoes counter current heat exchange with the water sprayed downwards; A small amount of water evaporates into the air to take away heat. and the cooled water is sprayed onto the coil to cool the high-temperature working fluid inside the coil. The humid and hot air is discharged by the axial flow fan at the top of the cooling tower. and the cooled working fluid flows to equipment such as the user side air compressor and freezer.