SMTE-T Series Cooling Towers

The SMTE-T series cooling towers are an advanced version of the SMTE series, designed to deliver superior cooling performance while maintaining energy efficiency and durability. This series incorporates cutting-edge thermal management technology, making it ideal for applications requiring high-efficiency cooling with minimal maintenance.

Key Features:

- Enhanced Heat Exchange Efficiency: Optimized design ensures faster and more effective cooling.

- Modular Counterflow Structure: Allows for easy installation, scalability, and adaptability to various cooling demands.

- Corrosion-Resistant Construction: Built with hot-dip galvanized steel, aviation-grade aluminum alloy fans, and fire-resistant filler for extended service life.

- Low Noise & Energy-Saving Fans: Axial-flow fans are engineered to minimize noise while maximizing airflow efficiency.

- Eco-Friendly Water Conservation System: Reduces water consumption while maintaining stable cooling performance.

Applications:

The SMTE-T series is widely used in:

- Industrial process cooling for manufacturing plants.

- HVAC systems in commercial buildings and large complexes.

- Data centers requiring precision cooling solutions.

- Energy and power generation facilities.

With its high-performance cooling capabilities, durable materials, and energy-efficient operation, the SMTE-T series cooling towers provide an optimal solution for industries seeking reliable and cost-effective cooling systems.

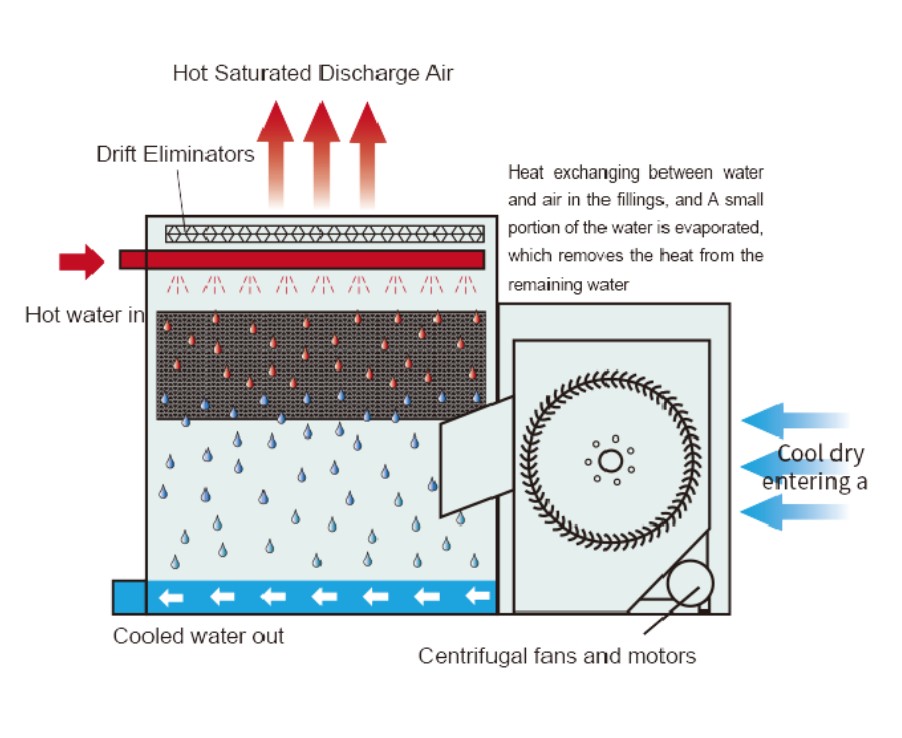

The hot water (marked in red) circulating from the user end flows into the internal water distribution pipeline of the cooling tower through the side inlet of the cooling tower. and is evenly sprayed onto the packing of the cooling tower through a large-diameter anti clogging nozzle; The centrifugal fan located at the bottom of the cooling tower blows dry and cold air from the side into the interior of the cooling tower. After entering from the bottom, the dry and cold air enters the cooling tower packing from bottom to top; Water and wind undergo counter current heat exchange in the packing layer, and a small amount of water evaporates into the air. The humid and hot air is discharged from the top of the cooling tower, taking away heat. The cooled water falls on the water tray at the bottom of the cooling tower, and the cooling water (marked in blue) circulates from the outlet of the water tray to the user end.

The SMTE-T open cooling towe adopts low rise single-sided air intake design, the overall height of the equipment is only 1900mm-2400mm. and the entire series has American CTI heat transfer performance certification. Under standard operating conditions. the water flow rate can range from 50 tons/hour to 300 tons/hour. The standard configuration includes Z-700 (G235) hot-dip galvanized steel sheet casing, aviation grade aluminum alloy ventilation fan, and patented fire-resistant filler. Suitable for central air conditioning in small commercial buildings, process water cooling in industrial plants, and data centers. especially suitable for restricted equipment sites and can be placed indoors.