SMCC Series Cooling Towers

The SMCC closed cooling tower adopts an efficient counterflow modular design, and the entire series has obtained the CTI heat transfer performance certification from the United States. Under standard operating conditions. the water flow rate can range from 50 tons/hour to 1200 tons/hour. The standard configuration includes Z-700 (G235) hot-dip galvanized steel sheet casing. aviation grade aluminum alloy ventilation fan. and integral hot-dip galvanized elliptical steel coil. Suitable for central air conditioning in large commercial buildings. process water cooling in industrial plants. and large data centers.

The SMCC series cooling towers are designed for high-efficiency heat dissipation, combining compact structure, energy-saving features, and durability. These cooling towers are ideal for industrial and commercial applications requiring reliable and long-lasting cooling solutions.

Key Features:

- Closed-Circuit Cooling System: Ensures a clean and contamination-free cooling process, making it ideal for industries that require pure water circulation.

- Corrosion-Resistant Construction: Built with galvanized steel, stainless steel options, and weather-resistant materials to extend service life.

- High-Efficiency Heat Transfer: Uses optimized coil designs and large-diameter anti-clogging spray nozzles for maximum heat exchange efficiency.

- Energy-Saving Fans: Low-noise axial-flow fans reduce power consumption while maintaining superior airflow.

- Easy Maintenance & Cleaning: Designed with accessible service doors and self-cleaning spray systems for hassle-free operation.

Applications:

The SMCC series is widely used in:

- Industrial cooling processes (manufacturing, chemical, pharmaceutical industries).

- HVAC systems in commercial and residential buildings.

- Power plants and energy-related facilities.

- Data centers requiring closed-loop cooling to protect sensitive equipment.

With its high-performance cooling, long-lasting durability, and energy-efficient operation, the SMCC series cooling towers are an ideal choice for industries demanding consistent and reliable cooling solutions.

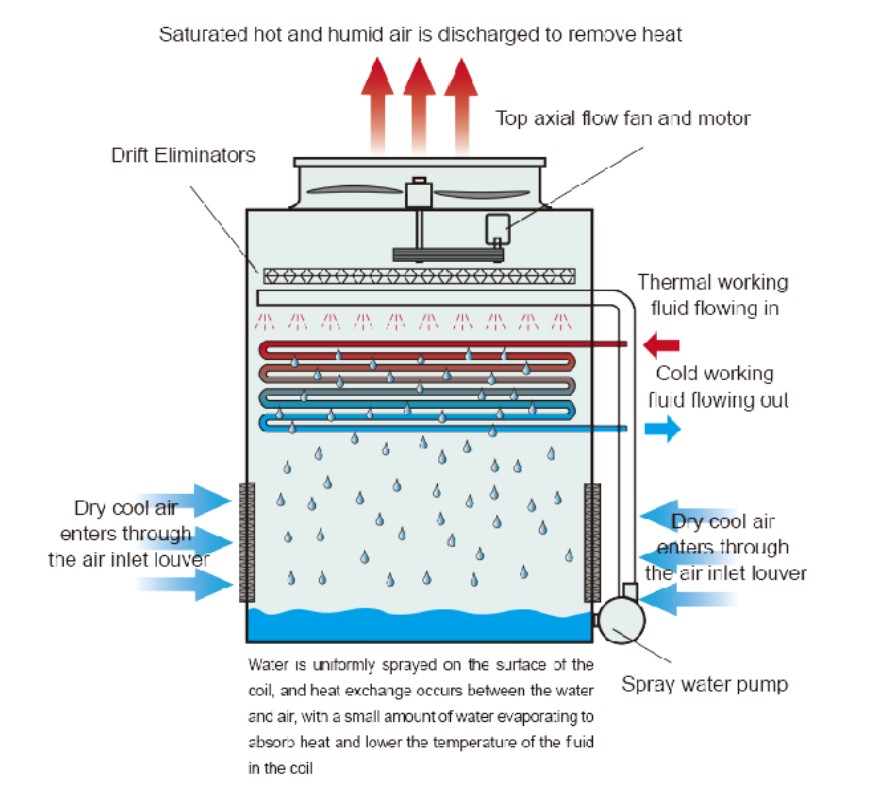

The hot fluid working fluid from the user end flows into the interior of the serpentine heat exchange coil through the side inlet of the closed cooling tower, while the external water in the water tray of the closed cooling tower is evenly sprayed onto the surface of the serpentine heat exchange coil through the bottom water pump and upper spray system: The axial flow fan located at the top of the cooling tower draws the surrounding dry and cold air into the interior of the cooling tower. The dry and cold air enters through the lower air intake grille and flows from bottom to top onto the surface of the serpentine heat exchange coil, where it undergoes counter current heat exchange with the external water on the surface of the serpentine heat exchange coil; A small amount of water evaporates into the air to take away heat. and the hot fluid working fluid inside the cooling coil is cooled. The humid and hot air is discharged by the axial flow fan at the top of the cooling tower, and the cooled fluid working fluid circulates to the user end.